Pump Chamber Refurbishment

We attended a site at a Care Home to refurbish a pump chamber – the site had been flooding and the stormwater drains backed up. One of the pumps was not operational and the floats were intermittent.

Over time pump chambers are subjected to rust and corrosion due to exposure to raw sewage, water and oil. This can be monitored by regular servicing. When corrosion is professionally monitored refurbishment can take place before pump failure – this means less downtime for you. Servicing and cleaning are vital in the prevention of failure to pump stations of all sizes.

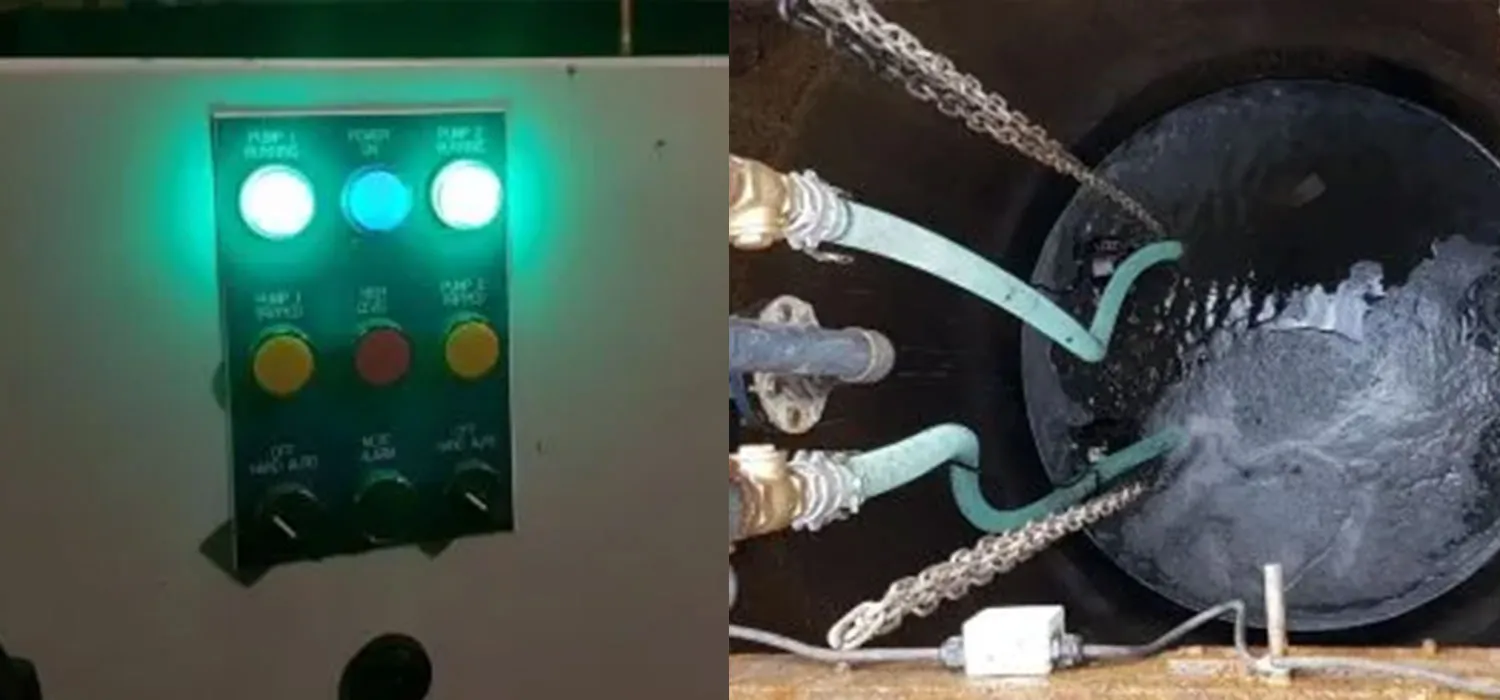

After replacing the control panel, float switches, pumps, non-return valves & clamps the team carried out a full tank empty and jet wash.

Pump repair and maintenance is a core element of our service provision. In many circumstances refurbishment should be considered over pump replacement, as it offers economic as well as practical advantages. Operational downtime can be reduced if our specialist pump engineers can carry out onsite repairs – however, we also offer offsite repairs at our fully equipped warehouse in Hampshire where our qualified team can carry out more in depth pump refurbishment. We hold in stock a wide range of spares including mechanical seals, bearings and belts which ensures a fast repair turnaround. Call us on 01420 561661 for your pump refurbishment requirements.