Subsumable Grinder Pumps: Installation, Maintenance, and Uses

In the realm of modern wastewater management, grinder pumps have emerged as indispensable components for both residential and commercial properties. These submersible pump solutions are specifically engineered to tackle demanding tasks—efficiently transporting wastewater from homes or facilities to the main sewer lines. As urban development expands into regions with complex terrains, the need for reliable wastewater solutions becomes increasingly critical. This guide explores subsumable grinder pumps with a focus on their benefits, maintenance, installation, and regional adoption across Hampshire and Surrey.

Key Takeaways

Subsumable grinder pumps (submersible sewage pumps) macerate solids into a slurry and move wastewater through small-diameter lines where gravity drainage isn’t feasible. They are widely used across residential and commercial sites.

This article covers their main advantages such as durability, clog prevention, and energy efficiency, along with best-practice maintenance and a step-by-step installation overview. It also highlights regional adoption in Hampshire and Surrey, including specialist providers such as Alton Facility Services.

What Are Grinder Pump Systems?

Grinder pump systems are a type of submersible sewage pump designed to manage wastewater where gravity alone is insufficient. These systems are especially valuable in hilly locations, low-lying properties, or sites located far from main sewer connections.

By enabling effective waste transport, grinder pumps allow even challenging properties to maintain reliable wastewater management and comply with environmental standards.

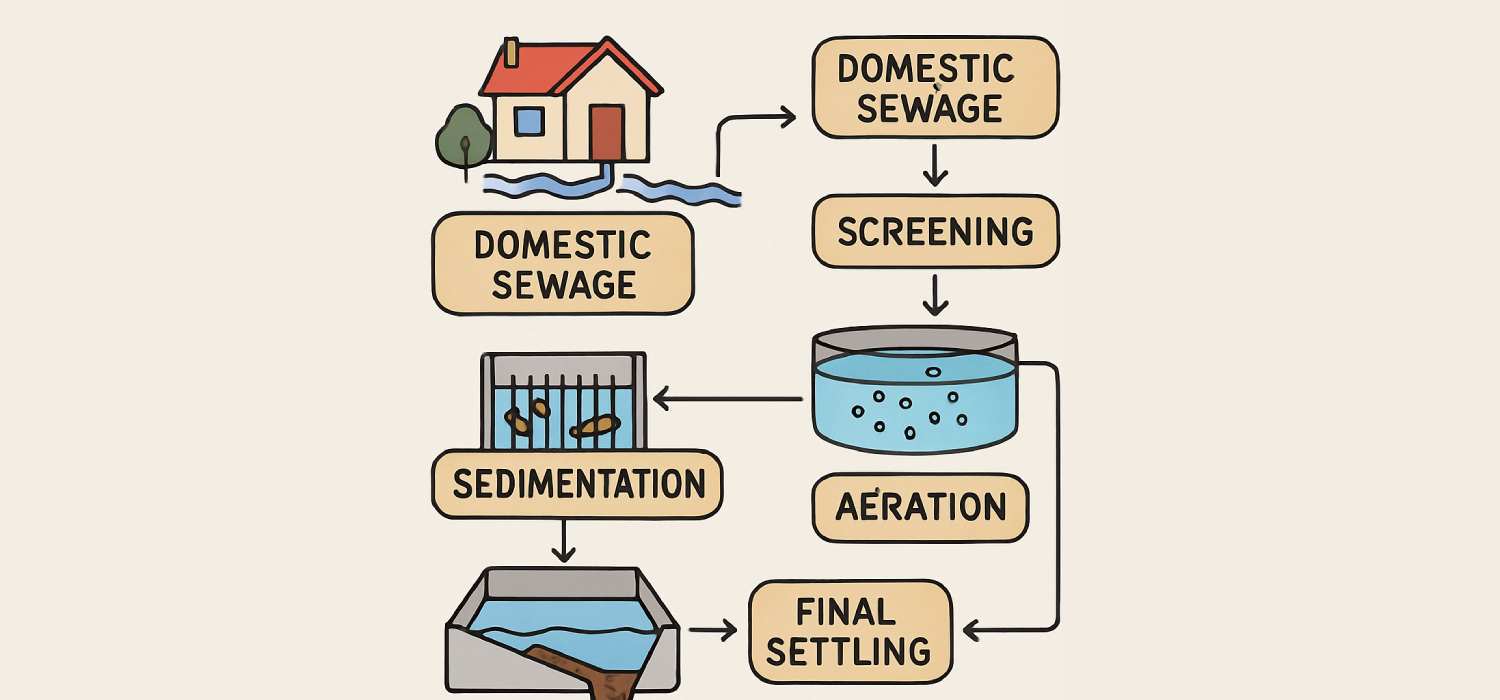

How Grinder Pumps Work

Grinder pumps operate by grinding solid waste into fine particles before pumping it through narrow pressure pipes into the main sewer network. This grinding process prevents clogs, supports continuous system operation, and helps avoid costly breakdowns.

Key Benefits of Subsumable Grinder Pumps

Durability and Reliability

Constructed with robust materials, subsumable grinder pumps are built to withstand harsh underground conditions and continuous use. Their long service life reduces the need for frequent repairs and replacements.

Powerful Grinding Performance

The internal cutting mechanism efficiently reduces waste into manageable sizes, preventing blockages and ensuring smooth wastewater flow through pressure pipe systems.

Ease of Installation and Maintenance

These systems integrate cleanly with existing plumbing and electrical infrastructure. With straightforward routine maintenance, they offer a dependable long-term wastewater solution.

Grinder Pump Maintenance Best Practices

Routine Inspections

Regular inspections help identify early signs of wear, corrosion, or mechanical issues before they develop into costly failures.

Cleaning and Flushing

Routine cleaning and flushing prevent debris buildup that could restrict flow or reduce system efficiency.

Professional Servicing

Periodic professional servicing ensures thorough system checks, optimal performance, and long-term reliability.

Grinder Pump Installation Process

1. Site Assessment

A full assessment considers elevation, distance to sewer connections, and anticipated wastewater volume to ensure correct pump selection.

2. Pump Selection

Choosing the right pump capacity, power rating, and construction type is essential for efficient operation.

3. Excavation

A stable, debris-free pit is excavated to house the pump assembly securely underground.

4. Setting the Pump

The pump is positioned level and firmly secured to prevent vibration or movement during operation.

5. Pipe Connections

Discharge pipework is connected using pressure-rated fittings to ensure leak-free wastewater transfer.

6. Electrical Connections

Electrical wiring must be installed safely and in accordance with regulations to ensure reliable pump operation.

7. System Testing

Final testing confirms correct grinding, pumping operation, and leak-free performance before commissioning.

Grinder Pump Services in Hampshire and Surrey

Hampshire

In Hampshire, Alton Facility Services delivers expert grinder pump installation, maintenance, and servicing for residential and commercial clients alike.

Surrey

Surrey hosts several reputable wastewater specialists offering tailored grinder pump solutions for domestic and business properties.

The Future of Grinder Pump Technology

Eco-Friendly Design

Manufacturers are producing energy-efficient grinder pump systems that reduce power consumption and operating costs while lowering environmental impact.

Smart Monitoring

Smart pump technology featuring real-time monitoring and remote management is set to improve system efficiency and reduce unexpected failures.

Conclusion

Subsumable grinder pumps play a vital role in modern wastewater management where gravity systems alone cannot cope. With correct installation and ongoing maintenance, they deliver reliable performance, public health protection, and long-term peace of mind.

Whether located in Hampshire, Surrey, or elsewhere, investing in a quality grinder pump system ensures efficient wastewater transport now and into the future.

Grinder Pump Q&A

What does “subsumable” grinder pump mean?

It refers to submersible grinder pumps installed underground that macerate wastewater solids into slurry and pump it through pressure pipes to the main sewer.

How do grinder pumps prevent blockages?

Their internal cutting blades reduce solids before discharge, allowing smooth flow and minimizing clogs.

What maintenance do grinder pumps require?

Regular inspections, routine cleaning, and periodic professional servicing ensure reliable long-term operation.

What does proper grinder pump installation involve?

Installation includes site assessment, pump selection, excavation, secure positioning, pipe and electrical connections, and full operational testing.

Who provides grinder pump services locally?

In Hampshire, Alton Facility Services offers complete grinder pump support, while Surrey features several reputable wastewater specialists.